Sep 29, 2025

In today's competitive dental industry, dental labs face the constant challenge of improving profit margins while maintaining the highest quality standards. Rising material costs, increasing case complexity, technician shortages, and ever-growing client expectations squeeze laboratories from multiple sides. Despite the pressure, cutting corners on quality is never a viable solution; costly remakes, loss of clinic trust, and reputational damage will quickly erode any short-term gains.

The good news: boosting profit margins without sacrificing quality is achievable. It requires working smarter, not harder, by streamlining workflows, making smart technology investments, optimizing resource allocation, and enhancing client relationships. This comprehensive guide dives deep into actionable, proven strategies for dental labs to improve profitability sustainably, supported by examples and practical tables to clarify impacts.

Balancing Profitability and Quality: Why Both Matter

Profit margin can be understood as:

Profit Margin = (Revenue − Costs)/Revenue

Dental labs generate revenue mostly through delivering prosthetics, crowns, and restorations with uncompromising quality. While reducing costs might seem straightforward, cutting quality leads to remakes, dissatisfied clients, compliance risks, and lost business. On the other hand, inefficient processes and waste erode margins even when quality is excellent.

The sweet spot lies in operational excellence, reducing inefficiencies while maintaining or improving quality.

Core Areas to Improve Profit Margins Without Cutting Quality

Focus Area | Profitability Strategy | Quality Impact |

|---|---|---|

Material Cost Management | Bulk purchasing, inventory control, vendor negotiation | Maintains material standards, avoids shortages |

Operational Efficiency | Lean workflows, automation, and bottleneck removal | Reduces errors, improves consistency |

Technology Investment | CAD/CAM, 3D printing, digital communication | Enhances precision and reduces manual errors |

Staff Training & Retention | Continuing education, cross-training, and ergonomics | Boosts technician skill, lowers remakes, and reduces burnout |

Outsourcing & Partnerships | Strategic outsourcing, supplier alliances | Access to expert skills and advanced technologies |

Pricing & Service Offering | Value-based pricing, premium service packages | Funds quality investments, differentiates the lab |

1. Material Cost Management

Materials often comprise a significant portion of lab expenses. Optimizing their management directly impacts margins:

Bulk Purchasing & Vendor Negotiation: Aggregating orders to leverage volume discounts lowers unit costs.

Inventory Control: Implement just-in-time systems with electronic tracking to minimize waste and prevent shortages.

Material Use Optimization: Training technicians reduces excess use and remakes from defects.

Case Example:

Labs adopting consolidated material procurement saved up to 15% in material costs without compromising restoration standards.

2. Boosting Operational Efficiency

Improved workflows cut production time and labor costs:

Adopt Lean Manufacturing Principles to remove non-value-added steps.

Use digital workflow automation to minimize manual data entry and follow-ups.

Identify and manage production bottlenecks via real-time tracking dashboards.

Standardize processes to lower training time and ensure consistency.

Efficient operations enhance turnaround time and decrease technician errors.

3. Strategic Technology Investments

Technology acts as a multiplier for both quality and efficiency:

CAD/CAM & 3D Printing: Automate design and manufacturing for precise, rapid, and repeatable outputs.

Integrated Digital Communication Platforms: Facilitate instant, clear communication between labs and dental practices, reducing misinterpretation.

AI Tools: Support margin marking, setup automation, and quality assurance.

The upfront costs are typically repaid through higher output, faster delivery, and fewer remakes.

4. Training and Retention of Skilled Technicians

Highly skilled technicians produce superior results more efficiently:

Provide ongoing education covering new materials and digital workflows.

Implement cross-training to increase workforce flexibility and cover peak demands.

Prioritize ergonomics and wellness to reduce physical strain and absenteeism.

Create career development and recognition programs to increase loyalty.

Engaged and skilled employees reduce errors and foster a culture of quality.

5. Intelligent Outsourcing and Strategic Partnerships

Consider outsourcing or collaboration for non-core or high-volume tasks to:

Expand capacity without permanent staffing increases.

Tap into specialized skills or advanced equipment.

Negotiate bulk discounts for materials or shared equipment.

Partnering smartly enables labs to focus resources on high-value services without degrading quality.

6. Pricing Optimization and Value-Added Services

Pricing aligned with value fosters profitability:

Use value-based pricing to charge according to case complexity rather than flat rates.

Offer premium services like expedited turnaround, cosmetic consulting, or digital smile previews.

Create bundled service offerings to increase average revenue per case.

Educating clients about value supports margin enhancement and funds quality initiatives.

Profit Margin Impact Table for Strategies

Strategy | Est. Profit Margin Improvement | Notes |

Bulk Material Purchasing | 5–15% | Requires strong supplier relationships |

Workflow Standardization | 10–20% | Lower training time, fewer errors |

Technology Investment | Variable, often high ROI | Initial costs offset by efficiency gains |

Staff Training | 5–10% | Reduces remakes, increases morale |

Outsourcing | Flexible, task-dependent | Increases capacity without hiring |

Strategic Pricing | 5–15% | Dependent on client communication |

Continuous Monitoring and Improvement: The Key to Sustainability

Improving margins is not a one-time event but an ongoing process:

Implement dashboards to track turnaround times, remake rates, material consumption, and technician efficiency.

Conduct periodic reviews to identify waste and improvement opportunities.

Incorporate feedback from technicians and clients for qualitative insights.

Embedding continuous improvement feeds profitability and quality steadily.

Conclusion

Improving profit margins while maintaining uncompromised quality in dental labs demands a holistic, data-driven approach. Smart material management, optimized workflows, technology adoption, skilled and engaged technicians, strategic outsourcing, and value-based pricing form the backbone of sustainable profitability.

Labs embracing these strategies not only increase their earnings but also strengthen their reputation, client loyalty, and operational resilience.

If you’re ready to elevate your dental lab’s profitability without sacrificing quality, explore tailored process optimizations and technology solutions to forge your path to success.

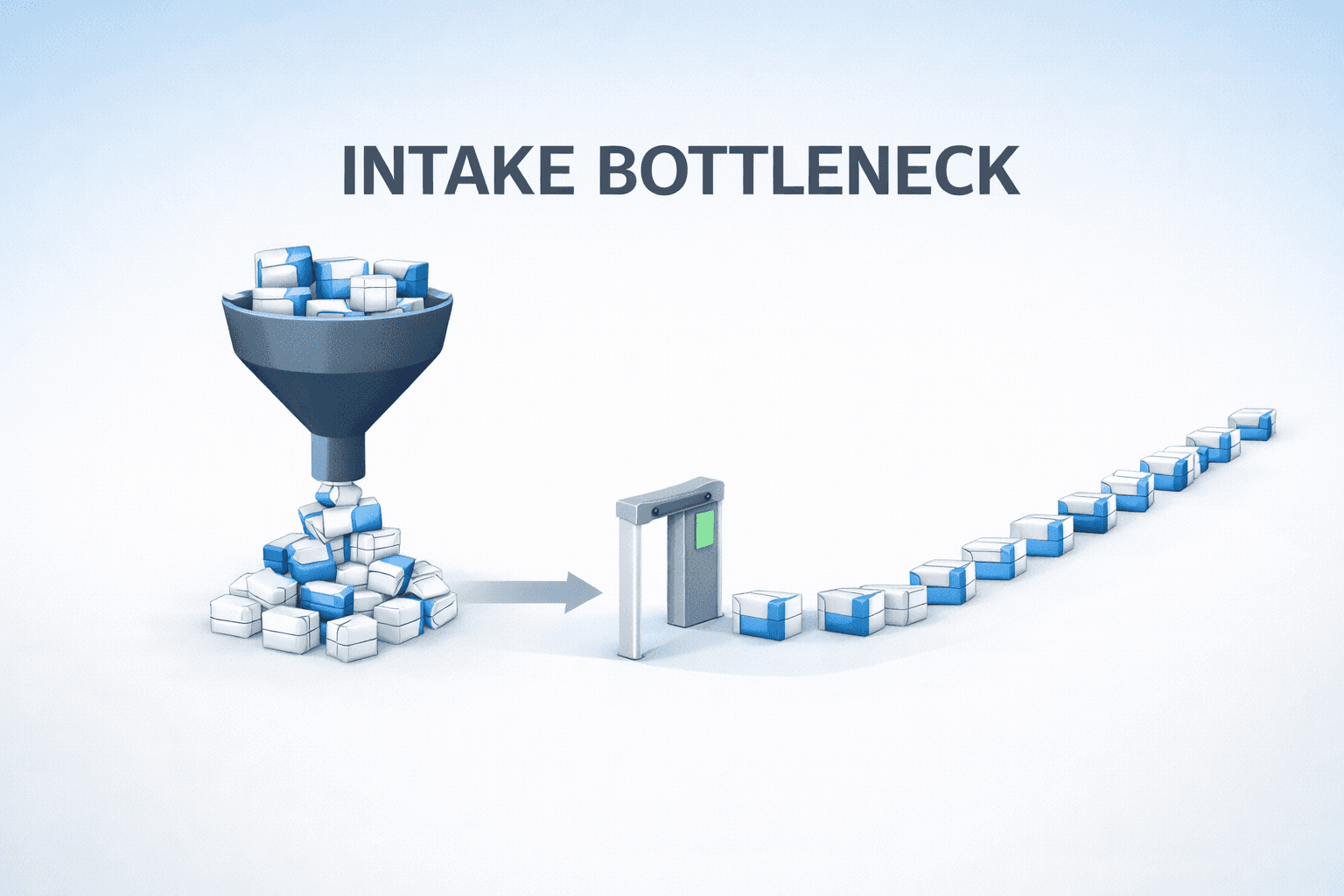

Intake Triage is Eating Your Best People

January 27, 2026

The Lab Became the Integration Layer (and nobody asked us)

January 27, 2026

Matt Everatt joins as an advisor to Smile Genius

December 18, 2025