Jul 31, 2025

Digital isn’t optional anymore; it’s your lab’s competitive edge.

In 2025, going digital isn’t just a “nice-to-have” for dental labs, it’s the difference between scaling efficiently and getting left behind. From real-time collaboration to automated workflows, digitization is transforming how modern labs operate, communicate, and grow.

Whether you're just starting or looking to fine-tune your tech stack, this guide breaks down everything you need to know to build a future-ready, digital-first dental lab.

Why Digitize Your Dental Lab Now?

Boost Efficiency: Automation streamlines manual tasks, minimizes errors, and accelerates case turnaround.

Seamless Collaboration: Digital platforms connect labs, dentists, and clinicians, enabling smoother teamwork.

Scalability: Grow your operations without the typical overhead headaches.

Data-Driven Decisions: Analytics help you track revenue, monitor key performance indicators, and identify growth opportunities.

Improved Patient Care: Faster, more consistent results enhance patient satisfaction and practice reputation.

Core Components of Digital Transformation

Cloud-Based Lab Management Systems

Adopting a cloud-based platform is foundational for dental labs in 2025. Benefits include:

Centralized Access: Securely store and access case data, digital impressions, and communications anytime, anywhere.

Automated Case Tracking: Manage every step robustly from case receipt to production to delivery without manual intervention.

Real-Time Communication: Built-in messaging enables instant conversations with dentists and technicians, reducing delays and misunderstandings.

Compliance Assurance: Encrypted data storage and audit trails ensure you meet HIPAA and GDPR requirements.

Digital Impressions and Scanning

Modern labs leverage intraoral scanners and digital impressions for greater accuracy and speed.

Integration with Leading Scanners: Support for popular devices like 3Shape, iTero, and Medit streamlines case data imports.

CAD/CAM Workflow: Move directly from impression to digital design and automated manufacturing, reducing human error.

Digital Archiving: Permanently store scans and design files securely for quick access and reproducibility.

Automated Production and 3D Printing

Digitization doesn’t stop at design labs now. Use advanced manufacturing tech:

3D Printing: Print crowns, bridges, models, or clear aligners onsite for rapid turnaround and precision.

CNC Milling Machines: Automate fabrication of prosthetics with high accuracy.

Material Management: Track resin, ceramics, and metals digitally for better inventory control and cost savings.

Digital Collaboration Platforms

Online portals and collaboration tools allow practitioners and labs to work together more efficiently:

Case Submission and Review: Clinicians submit, track, and approve cases digitally in real time.

Automated Notifications: Prompt stakeholders when approvals or additional info are needed.

Integrated Feedback: Questions or issues are addressed within the platform, reducing email overload.

Financial and Business Intelligence Tools

Digitization also streamlines financial operations:

Automated Billing: Instant invoicing and payment processing speed up cash flow.

Analytics Dashboards: Visualize revenue trends, outstanding payments, and operational metrics for better management decisions.

How to Successfully Digitize Your Dental Lab: A Roadmap

Steps | Actions |

Assessment | Evaluate current workflows, technology, and staff readiness |

Goal Setting | Define objectives such as reducing turnaround times, minimizing remakes, or improving tracking |

Vendor Selection | Research and select reputable providers for software, scanners, and manufacturing equipment |

Training | Provide hands-on training and certification for your team |

Implementation | Roll out digital tools in phases, starting with case intake and design workflows |

Integration | Connect your lab system with dental practice software like EHR and imaging tools |

Monitoring | Track KPIs and gather feedback regularly to optimize processes |

Overcoming Common Challenges

Change Resistance: Engage your team early by highlighting efficiency gains and celebrating small wins.

Cost Concerns: Consider the long-term savings from automation and error reduction against initial investments.

Learning Curve: Opt for intuitive platforms and invest in training to smooth the transition.

Data Security: Prioritize solutions that feature strong encryption and comply with relevant certifications.

Best Practices for Your Digital Lab

Start Small: Digitize case submission and communication processes before moving to full production automation.

Standardize Workflows: Document and enforce consistent digital procedures.

Leverage Data: Use business intelligence tools to identify bottlenecks and opportunities.

Stay Up-to-Date: Regularly update your software and attend industry events to stay current with innovations.

Future Trends in 2025 and Beyond

AI-Driven Planning: Automated treatment plans, smile simulations, and QA

Remote Collaboration: Real-time video approvals and design reviews

Smart Materials: Advanced digital tracking of resin and ceramics

Sustainable Ops: Reduce waste and carbon footprint with digital approvals and local production.

Final Takeaway: Digital = Scalable + Sustainable

Digitizing your dental lab is no longer about convenience, it’s about survival and scale. From enhancing patient outcomes to building better dentist relationships, a well-executed digital strategy is your lab’s growth engine for the future.

Ready to Go Digital?

Let’s talk.

Book a free consultation with our experts to learn how Smile Genius can help you streamline operations, build stronger clinic relationships, and scale your lab with confidence.

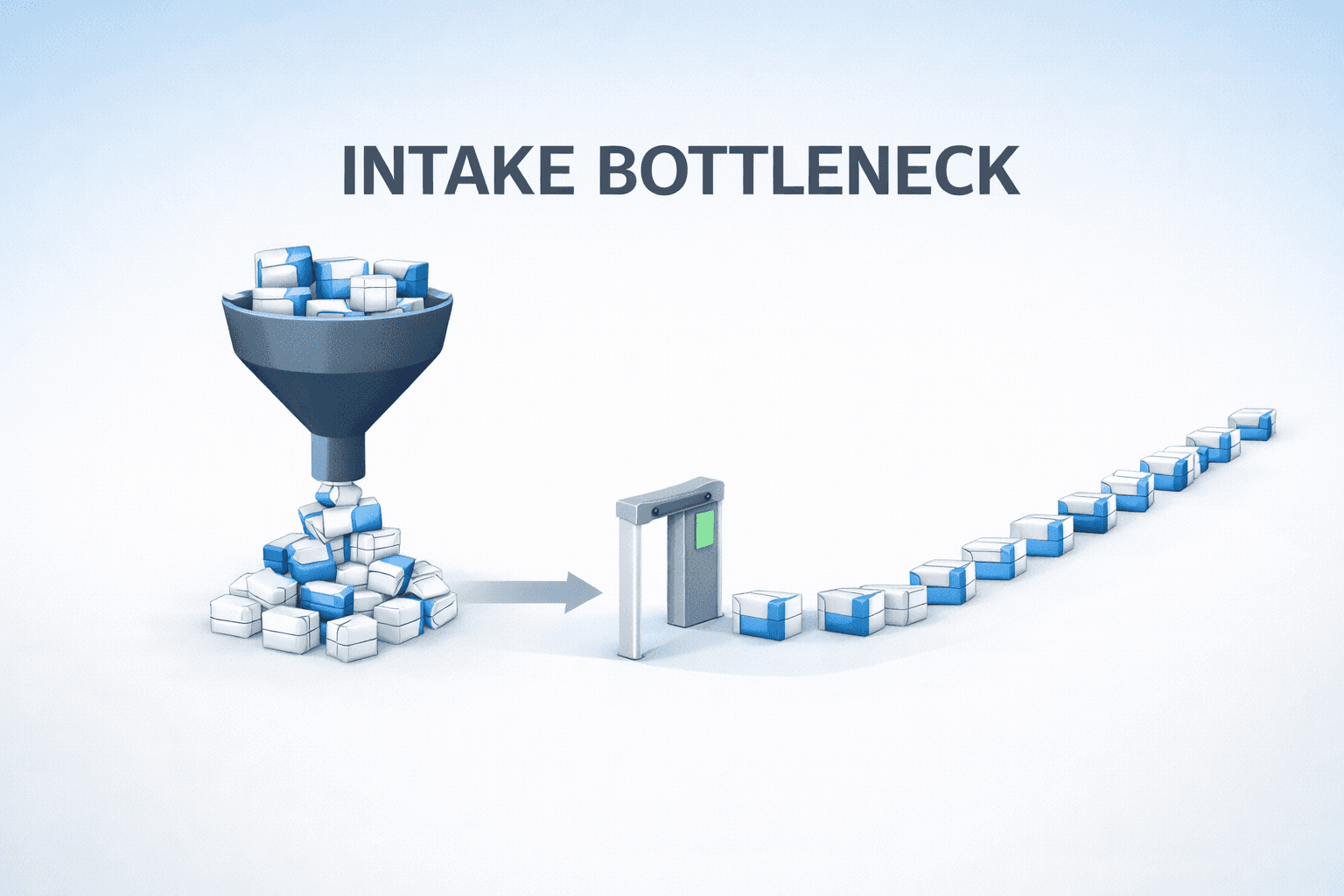

Intake Triage is Eating Your Best People

January 27, 2026

The Lab Became the Integration Layer (and nobody asked us)

January 27, 2026

Matt Everatt joins as an advisor to Smile Genius

December 18, 2025