Aug 15, 2025

Innovation, funding and regulatory shifts signal a new era for orthodontic workflows — here’s why lab owners and operations leaders should pay attention.

Introduction – A market at an inflection point

The clear‑aligner industry is no longer a sleepy niche; it is a battleground of global device makers, venture‑backed start‑ups and academic researchers pushing the boundaries of biomechanics and digital care. Recent months have brought product launches, funding announcements, and even a high-profile retreat, each hinting at how the next generation of aligner therapy will be designed, manufactured, and managed. For dental laboratories and DSOs that provide orthodontic services, understanding these signals is not just interesting gossip, it’s essential for strategic planning.

New biomechanics mean new workflows

At April’s American Association of Orthodontists meeting, Align Technology unveiled the first Invisalign system with built‑in occlusal blocks for mandibular advancement. This Class II product simultaneously advances the lower jaw while straightening teeth, using Align’s SmartTrack material and proprietary force‑control features. For labs, the implication is that clear aligners are expanding into cases once reserved for functional appliances. Designing and producing these aligners will require close coordination with orthodontists and an appreciation for how occlusal‑block geometry interacts with tooth movement. Materials and QC protocols may need to evolve to handle solid components embedded in flexible trays.

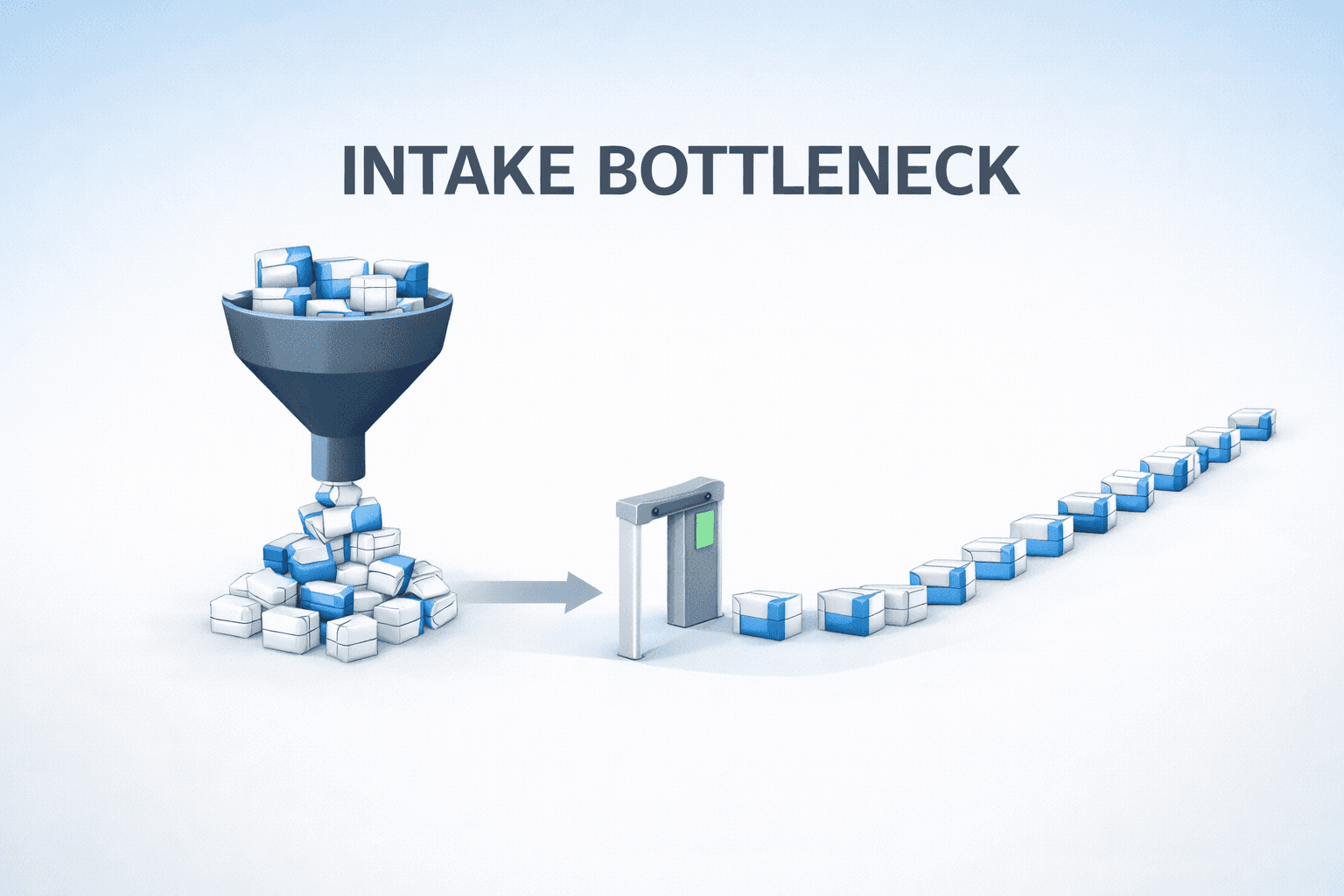

A few days later, the innovation spotlight shifted to OrthoFX. The San‑Francisco‑based company announced “Rescue” aligners intended to get off‑track treatments back on course. Coupled with an AI‑powered monitoring tool, FXOnTrack, these aligners can be approved and shipped within a week, a speed unheard of in traditional case resets. Rapid turnaround will test the agility of labs. Shorter production cycles leave less room for bottlenecks; digital case intake, design sign‑offs and fabrication must be tightly integrated. As more products pair AI monitoring with on‑demand manufacturing, labs that still rely on spreadsheets and phone calls risk falling behind.

Start‑ups and capital – global competition heats up

Innovation isn’t just coming from Silicon Valley and Arizona. Singapore‑based Dr Clear Aligners secured an $8 million Series A led by Insignia Ventures Partners. The start-up plans to use the funding to expand into the Middle East and North Africa, deepen its Asia-Pacific footprint, and invest in artificial-intelligence monitoring technology. With operations in seven countries and a network of over a thousand partner clinics, DCA demonstrates how quickly regional players can scale when they pair a consumer‑friendly brand with in‑house clinical expertise. For North American labs that export aligners or provide design services, the takeaway is clear: competition is global. APAC firms are raising capital, leveraging AI and moving into new geographies. That means the bar for service quality and turnaround times will rise everywhere.

Regulatory headwinds and market realignment

Not all news has been celebratory. In October 2024, dental‑equipment giant Dentsply Sirona suspended sales and marketing of its Byte aligners after consultations with the U.S. FDA. Byte was a high‑profile acquisition in 2021 that gave Dentsply a direct‑to‑consumer channel. Now, regulatory uncertainty and declining conversion rates have forced the company to rethink its investment. The message to labs is twofold: direct‑to‑consumer orthodontics is not immune to oversight, and regulators are paying closer attention to patient safety. Laboratories that partner with mail‑order platforms should be prepared for stricter compliance requirements and potential disruptions.

Align Technology also issued a sobering update. Citing macroeconomic uncertainty and a drop in elective procedures, the company cut its 2025 revenue outlook from mid‑single‑digit growth to flat. Leadership plans to realign business units, reduce headcount and regionalise manufacturing to improve efficiency. Even the market leader feels pressure to streamline operations as patient starts softening. For labs, this underscores the importance of cost control and adaptability. When demand ebbs, efficient case management and clear visibility into production capacity become competitive advantages.

What it means for labs and Dental Groups

The overarching theme across these stories is that the aligner industry is stretching in multiple directions at once. On one end, there’s a race to develop more sophisticated biomechanics, occlusal blocks, AI‑monitored rescue trays, even shape‑memory materials coming out of academic labs, which will demand new manufacturing capabilities and closer collaboration between clinicians and technicians. On the other hand, there’s a regulatory and economic environment that rewards efficiency and transparency. Venture‑backed start‑ups are eyeing global expansion while established giants are consolidating and focusing on core strengths.

In practical terms, lab owners and operations executives should view these developments as a call to modernise. Digitised prescriptions, real‑time case tracking and integrated billing aren’t “nice‑to‑have” features anymore; they are prerequisites for participating in a market where cases can be approved and shipped within days. Similarly, the ability to centralise communication across orthodontists, general dentists and patients helps labs navigate compliance issues and respond quickly when treatments deviate from plan. Software platforms that orchestrate these workflows, from intake to production to invoicing, can free teams from administrative overhead and allow them to focus on quality and innovation.

Finally, staying engaged with regulatory bodies and professional associations is just as important as keeping up with technology. The American Association of Orthodontists’ call for clinicians to report adverse events to the FDA illustrates that the bar for oversight is rising. Labs that maintain rigorous documentation and open channels with providers will be better positioned to handle future scrutiny.

Conclusion – Prepare for the next chapter

The clear‑aligner sector is evolving from a disruptor to a mature segment of orthodontics. Growth is still evident, but competitive pressure, technological leaps and regulatory check‑ups accompany it. Dental labs and DSOs that embrace digital workflow platforms, cultivate partnerships across the supply chain and keep a close eye on global trends will be best placed to thrive. The future may still be about straightening teeth, but the path there is getting a lot more sophisticated.

Intake Triage is Eating Your Best People

January 27, 2026

The Lab Became the Integration Layer (and nobody asked us)

January 27, 2026

Matt Everatt joins as an advisor to Smile Genius

December 18, 2025